Spartan Blades, along with other tactical knife manufacturers, have embraced the high performance CPM steels for their knives. S30V, S35VN, and now S45VN. If you’re also a steel nerd like myself, you know the advantages and disadvantages of S30V, which has long been an industry standard and still continues to be. S35VN improves upon S30V with the ability for it to be worked easier on the manufacturer end as well as the end-user end with resharpening. In addition, S35VN offers improved toughness and edge holding over S30V. so, you get a better steel that is not as difficult to work with and resharpen. Still, you see a lot of S30V used now for the higher end knives and that is probably more economic driven more than anything, as manufacturers probably are getting a great price for S30V in bulk sheets. Some already have made the switch to S35VN such as Spartan Blades has, since it is about 15 to 20 percent tougher than S30V without any loss of wear resistance. They have found this steel to be ideal for their knives, with the bulk of the product line being tactical oriented, so edge holding and toughness are key elements in a steel for these types of knives that are designed and built to go the distance, sometimes in unforgiving conditions and circumstances. Not only do tactical knives benefit from steels like S35VN, but also hunting knives and survival knives as well, for the very same reasons as well. Edge holding is a major qualification for these knives for the way they are used.

The Spartan Blades SHF 3.25 is the first Spartan model to come with S45VN steel

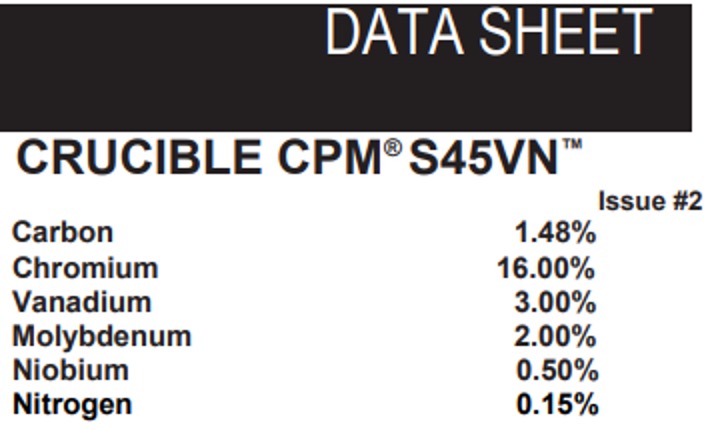

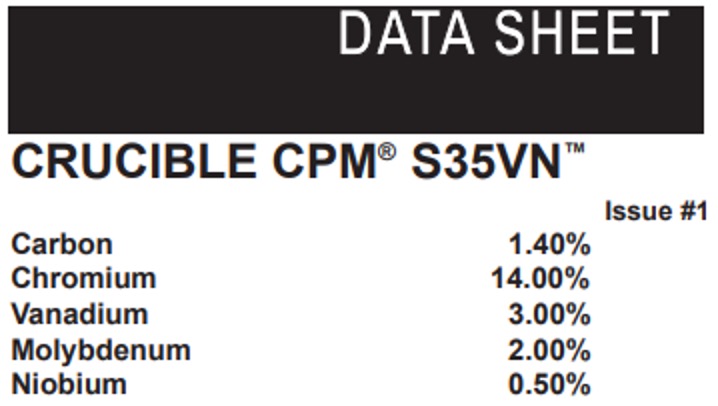

So presently, there is an ever so gradual shift from S35VN to S45VN in the knife industry. Spartan Blades is one of the companies who is making an in-line switch, the other company I am aware of is Chris Reeve Knives. There may be more that I am not aware of. No doubt in time, there will be more manufacturers who will follow suit. Plinking around the internet and scouring for information on S45VN, I’ve come across several discussions on the “S35VN versus S45VN” topic. People are starting to ask questions. People want to know! Knife folks are very astute and want to learn all they can about the materials and technology. Is S45VN really better than S35VN? The answer may surprise you. Yes, it is a better steel than S35VN but there’s not a great difference. They basically are alike with the exception than S45VN has a little bit more carbon and chromium in the mix, along with the addition of nitrogen - which S35VN does not have. What exactly does all this mean? It means that S45VN has improved edge retention, wear resistance, corrosion resistance, and toughness over S35VN. Basically, Crucible Industries - the maker of CPM steels - was able to tweak S35VN to make it perform even better. For knife manufacturers who constantly strive to make in-line improvements to their products, switching to S45VN makes sense. It’s a way they can keep their knives performing optimally. The Spartan Blades SHF 3.25 is the first Spartan model to come with S45VN steel, look for the other existing Spartan Blades tactical knives to be switched over gradually to S45VN. On the consumer end, the consumer may not notice this difference, it’s nothing that you can chart and keep track of. Still, let this not influence your decision of “S35VN versus S45VN”, as they both are great steels and will definitely go the distance for you. But any sort of improvement to blade steel that increases its edge retention capabilities and improves toughness is definitely welcome, and nice to have. Plus, knife guys like to have the latest-and-greatest blade steels. Though, this in no way means that S35VN and even S30V are inferior steels, and are ideal to use in tactical, rescue, hunting, and survival use.

CPM S35VN and S45VN Developed and made by Crucible Steel in the United States

Data tables above sourced from CPM S35VN and CPM S45VN data sheets from Crucible Industries

Data tables

In the ever changing pursuit of the latest-and greatest in materials for making knives in both the production and custom markets, knife makers and manufacturers are always on the lookout for materials that have improved performance for the price. It’s what the consumers want. Be on the lookout for the switchover to S45VN in all Spartan Blades knife models as well as other manufacturers as well. All the CPM steels are made using a process that converts particles into a homogenous steel. These steels typically have superior grindability, toughness, and dimensional stability compared with other steels that are manufactured by more conventional melting methods. In general, CPM steels offer enhanced performance that other steels cannot offer. CPM steels are an industry standard with high end production knives and custom knives.