Why we made the small Enyo knife

Nov 18th 2015

The Enyo

Why such a small knife

Ever hear the phrase “good things come in small packages”? This is one we hear all the time in regards to our little Enyo blade. The Enyo is a small neck knife that that we designed several years ago that continues to become of our top sellers.

We received a phone call from a soldier in Iraq who worked for a Provisional Reconstruction Team or PRT. These teams were tasked with the rebuilding and construction of Iraqi hospitals, schools and bridges. He explained that they were in the process of conducting shuras or meetings with local village elders. The purpose of which is to decide the affairs of the communities they were working in. As you can imagine, these meeting can get pretty heated and entering a Shura wearing a helmet and carrying a machinegun doesn’t always help. This is why the soldiers wanted a small fixed blade knife that could be worn but not seen.

Simultaneously, we were receiving requests from our civilian customers to make a neck knife, commonly referred to as a “necker”. The timing seemed right, so we made the decision to move forward on a design. While we knew that the knife would never become a government project, we figured we would apply a little military twist on it's design process. We were going to make the blade as if we were in the military and preparing a Critical Needs Statement. A Critical Needs Statement is a document we learned to write in the Army. It was basically a way of convincing the Chain of Command that you really needed something and why they should buy it for you.

Fortunately, we live on the back side of Ft Bragg and still have many active duty friends and family. We talked to them at length and we came up with several requirements for the knife.

- Must be under 6.5 inches if concealed

- Blade length no longer than 3 inches

- Comfortable in the hand

- Good edge retention

- Not too thick so that it could be carried in the waist band

- Have a Kydex sheath for airborne operations

- Match the digital and OCP uniforms (Less trouble with the 1SG…Really!)

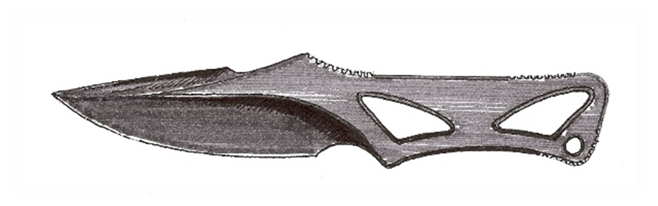

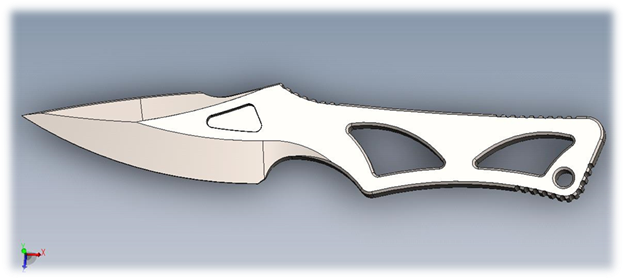

(Final drawing of the Enyo)

With these guidelines in place, we started the design process not realizing that the process would take a little longer than we thought. You see the problem was, “how do we make a usable knife with such a short length requirement”? We have a saying here at Spartan “a knife should be three things: sharp, pointy, and fit in the hand.” We quickly realized that doing these three things would be a bit difficult and considered not making the knife at all.

After a little more work, we developed a design that met our requirements and fit in the hand. The trick was to incorporate a thumb notch on the distal side of the blade allowing the user to choke up a bit. (See picture below) This is a feature we liked so much that we added it to our Phrike and Pallas blades becoming a recognizable “Spartan Blades feature".

Additionally, we placed a small lanyard bead on the rear of the knife to allow the user’s pinky finger a little more purchase. The result was the user could now place his whole hand on the knife. (See picture below)

With this final design in hand we moved forward with the computer modeling and production process

The Enyo is now one of our most popular knives and carried the world over. The popularity of the blade continues to grow in part because the blade length of only 2 11/16 makes this little knife legal almost everywhere!